ENVIRO REMEDIATION AND RESEARCH LABORATORY

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to ENVIRO REMEDIATION AND RESEARCH LABORATORY

Corrosion Analysis

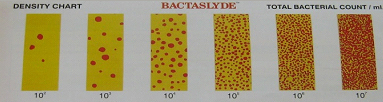

One of the major economical loss (billions of dollars in each year) faced by the oil and gas companies is due to the internal corrosion of the pipelines caused by sulfate reducing bacteria (SRB). The growth of SRB and their secondary metabolites in pipelines cause surface modifications, which can induce a more-complex corrosion process. Sulphate-reducing bacteria are known to generate H2S as a by-product of their respiratory cycle, thereby contributing to the deleterious role in the plugging of injection wells, corrosion of equipment, and biofouling (biofouling refers to the formation of microbial deposits or biofilms on virtually any surface submerged in an aqueous environment. Crude oil and its by-products contain nutritive compounds, therefore they represent a favourable environment for microbial growth, which may cause not only hydrocarbon consumption but a detriment in physicochemical and operational properties of products, leading to economic loss and even accidents due to filter saturation and pipiline and equipment corrosion. Metal coupon analyses are frequently utilized to estimate the effects of corrosion and fouling within industrial operating systems. In this testing, a coupon of the same type metal used in the system component is weighed and deployed in the plant environment. The samples are then collected after exposure and analyzed for evidence of biofouling or corrosion. SRBs then detected by standard MPN method in the oil and gas industry.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.